Tapestry and Vector

Tapestry helps New Zealand’s largest electric utility, Vector, reduce inspection times and boost resilience

Inspecting the grid is a grind. Repairing power lines in the remote bush, trimming suburban tree overgrowth, responding to power outages, and spotting infrastructure issues before they become problems—these are just some of the tasks that Field Assessment Managers like Richie Inglis do everyday to ensure that electricity flows to consumers and businesses with as few interruptions as possible.

Richie works for Vector, New Zealand’s largest electric distribution utility. His job—inspecting and repairing the grid to ensure power remains reliable for more than 1.7 million residents in and around Auckland—is only getting harder as demand for power surges, extreme weather events become more common and the grid’s future grows more complex.

It’s challenges like these that my team at Tapestry have been exploring as we build our moonshot for the electric grid. For the last five years, we’ve been working with Vector to learn how tools like AI, computer vision and machine learning can transform grid management, maintenance and planning.

Vector, New Zealand’s largest electric distribution utility, has been using Tapestry’s AI-enabled tools to inspect critical assets more quickly, reduce the time and effort required to inspect poles in inaccessible terrains and plan for a stronger and more resilient future grid.

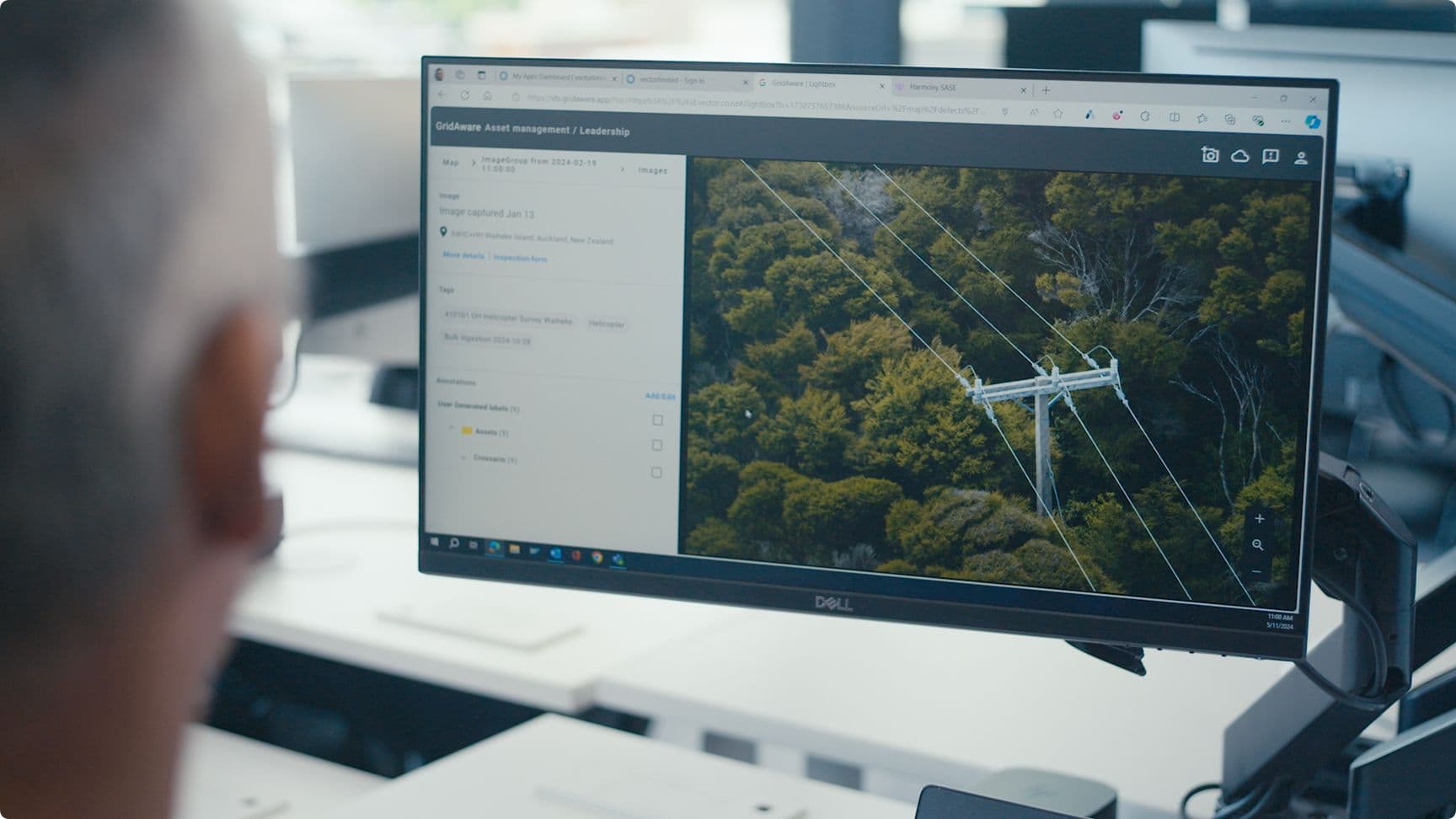

Today, we’re delighted to share some promising results from our partnership. By applying computer vision and machine learning to high-resolution aerial imagery, Tapestry’s AI-enabled tools have made it much faster for Vector to inspect its critical assets, like utility poles and transformers, and much easier to spot and address issues before they become problems.

New data from Vector shows that using GridAware, Tapestry’s grid management and intelligence platform, Vector has significantly reduced the time it takes to inspect the companys' roadside poles. Inspections that once took 30-45 minutes per pole can now be accomplished in just 5 to 7 minutes—that’s 83% faster.

Vector's data shows that Tapestry has also dramatically reduced the time and effort required to inspect poles in inaccessible terrains. On remote Kawau Island, for example, an inspection process that once required 320 hours of strenuous onsite work for a team of eight now takes approximately 12 hours using GridAware—a 96% reduction in the time and effort previously required to inspect equipment across the sprawling 5,000-acre island.

Improved network visibility

Faster inspections of road-accessible poles

With GridAware, Vector has a powerful new tool to make the traditional network inspection process more efficient, so its expert technicians can spend more time on maintenance that enhances reliability for customers—and less time backing up the truck or bashing through the bush.

As Tapestry has grown, we’ve learned an important lesson: developing cool technology only matters if it’s used and useful. And quantifying specific metrics about your technology’s impact is only possible if a partner like Vector is willing to share hard data.

The insights Vector is gleaning from applying machine learning and AI to its physical assets are not only supercharging their field team's productivity, they’re also helping Vector create richer maps and insights to transform their future planning.

Vector has been piloting Tapestry’s Grid Planning Tool for Distribution, our next-generation planning tool, which enables utilities to rapidly test and evaluate a myriad of simulated scenarios to better understand how future changes in weather, demand, or other factors may push the grid to its limits. As Andre Botha, Vector’s chief engineer, explains it, “We can now do a study for an area on the network in days, instead of weeks. Tapestry has changed all that.”

Andre Botha, Chief Engineer at Vector“We can now do a study for an area on the network in days, instead of weeks. Tapestry has changed all that.”

Armed with that knowledge, Vector’s grid planners will be able to not only improve how they manage the network they have today (using GridAware), but anticipate how to build a stronger, more resilient distribution network far into the future—even as the growth of customer-owned devices like batteries, rooftop solar and electric vehicle chargers shift how and where energy flows into and across the grid.

Our team founded Tapestry eight years ago because we could see the transformative potential for AI to bring the grid out of the industrial age and into the age of intelligent technology. Vector’s experiences and data showcase the promise that AI can have a positive impact on the electrical grid. And, since the physics of the grid are the same whether you’re in New Zealand, Nebraska or New Delhi, it’s also a hopeful glimpse into how AI may one day help *any* company distributing electricity to strengthen its grid.

If you’re interested in learning more about our partnership, and lessons for other utilities navigating these same shifts, check out our case study here. And if you’re interested in joining us as a partner or a member of our team, please get in touch at: tapestryteam@x.team.

Before joining Tapestry at X, The Moonshot Factory, Page held roles as a go-to-market and commercial leader and advisor at several start-ups, two of which attained unicorn status: Sunrun in rooftop solar energy in the U.S., and Konfio in financial services in Mexico. She was previously co-CEO and founder of Clarus Power, a venture-backed residential solar customer acquisition platform. She was recognized as one of the top 50 Climate Tech Operators in the 2021 Climate Draft and won Fin Earth’s 101 Women in Climate Award in 2024.